The Lab report

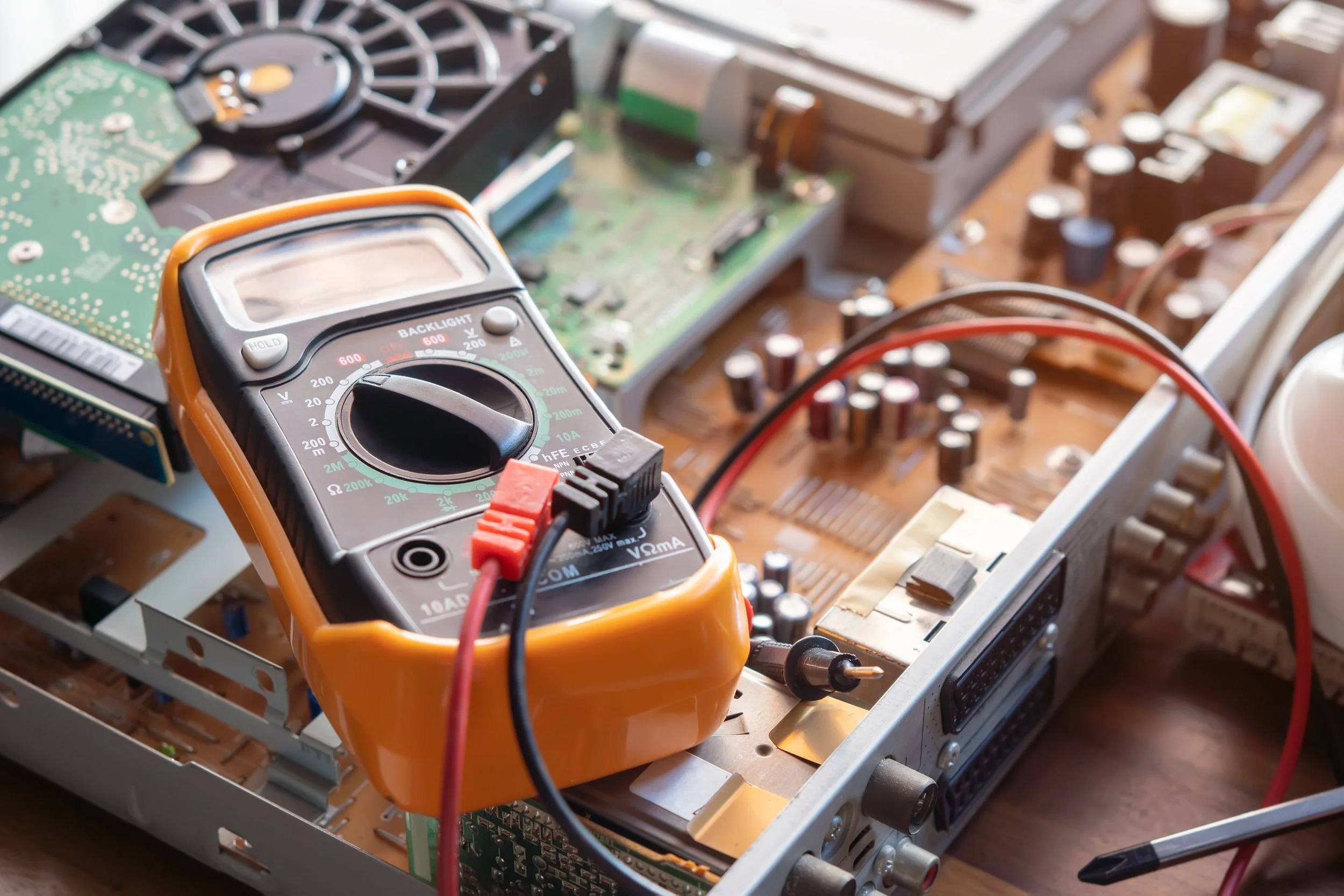

The Hidden Cost of Out-of-Tolerance Instruments

Out-of-tolerance instruments create far more risk than most teams realize. From costly recalls to safety issues and audit failures, even a small measurement error can lead to serious problems. Learn how consistent calibration protects your operation, your customers and your reputation.

We Don’t Give You Time to Miss Your Tools

When tools are out for calibration, work can slow down fast. Tool Testing Lab’s five-day turnaround guarantee and 2.5-day average turnaround mean your equipment gets back to work quickly. Learn how fast, reliable calibration keeps operations moving without compromising accuracy or quality.

Onsite vs. In-Lab Calibration: Which Is Right for Your Tools?

Choosing between onsite and in-lab calibration depends on your tools, environment, and downtime needs. Learn the key differences and how to decide which option makes the most sense for your equipment.

Traceability vs. Accreditation: What Is the Difference?

Traceability and accreditation are often used interchangeably, but they are not the same. Learn the difference and why it matters when choosing calibration services for your tools.

Why ISO 17025 Accreditation Matters (and What It Really Means)

ISO 17025 accreditation proves a calibration lab’s technical competence, accuracy, and traceability. Learn what it means and why it matters when choosing a calibration partner.

How to Choose a Calibration Partner You Can Trust

Choosing a calibration provider is about more than speed or cost. A trusted partner protects your measurements, compliance and reputation. Learn what to look for in a calibration lab and how the right partner supports accuracy and confidence.